Clamping force:10T to 500T;

Injection weight: 35g to 850g;

Vertical four columns clamping, vertical injection, suitable for insert injection molding process;

1 top mold,2 bottoms mold design;

Table slid out ,put insert part into outer mold and inner mold injection at the same time, effective to improve production capacity;

Flexibility and safety. We can upgrade to servo motor forcustomer's need, the actual energy save 50%~70%.

| MODEL | KS-45T-2S | KS-60T-2S | UNIT | ||||||

| INJECTION UNIT | Screw Diameter | Ф25 | Ф28 | Ф32 | Ф28 | Ф32 | Ф36 | mm | |

| Theory of injection quantity | 63.8 | 80 | 104 | 80 | 104 | 132 | cm3 | ||

| Injection quality | 59.3(2.1) | 74.4(2.6) | 96.7(3.4) | 74.4(2.6) | 96.7(3.4) | 122.9(4.3) | g/oz | ||

| The maximum injection pressure | 192(1960) | 153(1563) | 117(1195) | 212(2170) | 162(1661) | 128(1312) | Mpa(Kgf/cm2) | ||

| Injection rate | 53 | 67 | 87 | 73 | 95 | 121 | cm3/s | ||

| Injection speed | 110 | 118 | mm/s | ||||||

| Rate of increase | 220↑ | 164(45T) | mm/s | ||||||

| Screw ratation speed | 0~240 | 0~240 | r p m | ||||||

| Nozzie highlight the template size | ≥45 | ≥45 | mm | ||||||

| CLAMPING UNIT | Clamping force | 441(45) | 588(60) | KN(tf) | |||||

| Clamping stroke | 200 | 200 | mm | ||||||

| Min. mold thickness | 150(200) | 180(260) | mm | ||||||

| Max. opening | 350(400) | 380(460) | mm | ||||||

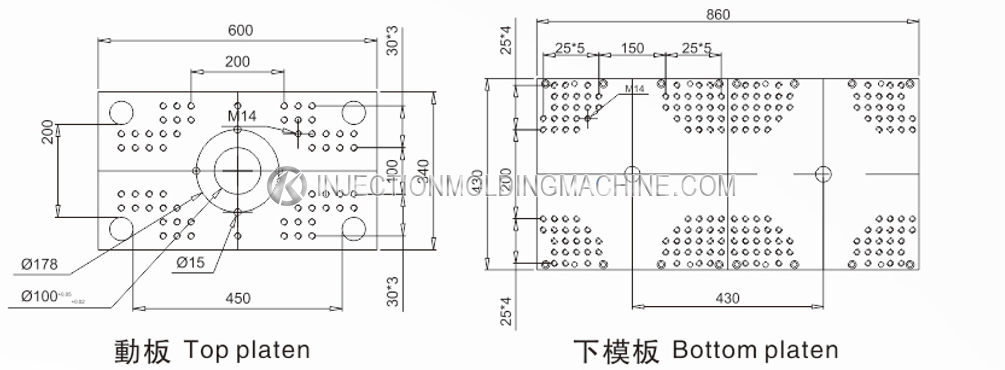

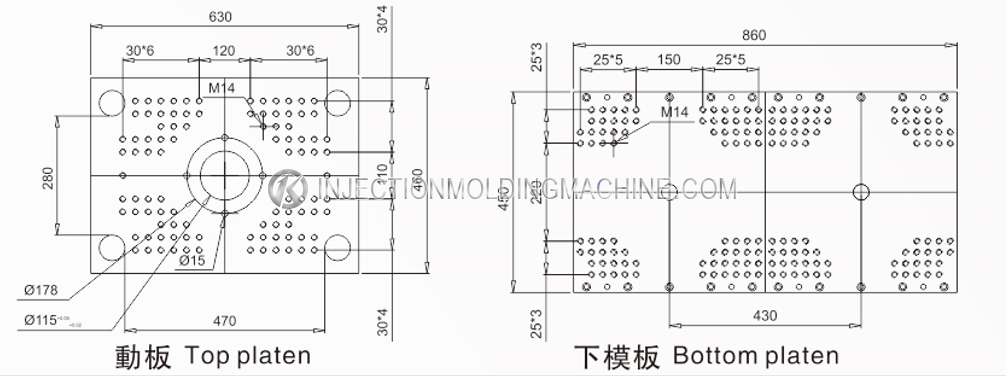

| Distance between tie bars | 410*250 | 460*330 | mm | ||||||

| Max. mould size | 350*250 | 390*300 | mm | ||||||

| Ejector Distance | 75 | 100 | mm | ||||||

| Ejector Force | 26.5(2.7) | 26.5(2.7) | KN(tf) | ||||||

| OTHER | System pressure | 13.7(140) | 13.7(140) | Mpa(kgf/cm2) | |||||

| Oil tank capacity | 200 | 230 | L | ||||||

| Motor power | 7.5(10) | 11(15) | KW(HP) | ||||||

| Machine dimensions | L*W | 1.7*1.4 | 1.8*1.7 | M | |||||

| H | 2.8 | 3.1 | |||||||

| Machine weight | 2.1 | 2.6 | tf | ||||||

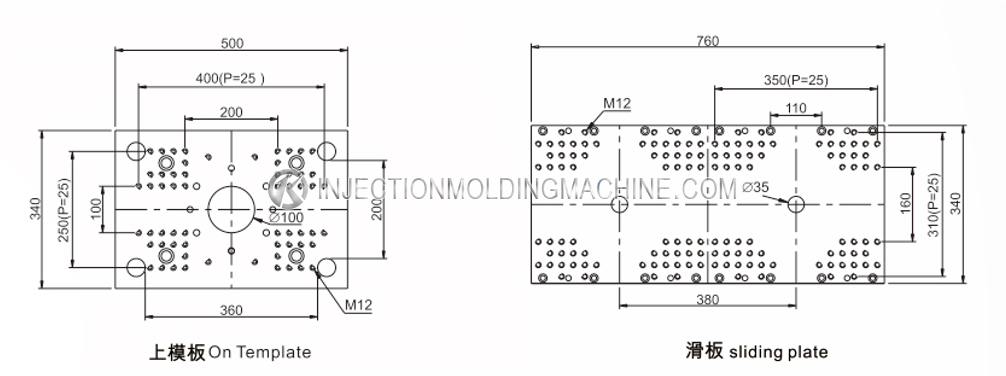

| KS-45T-2S | KS-60T-2S |

|  |

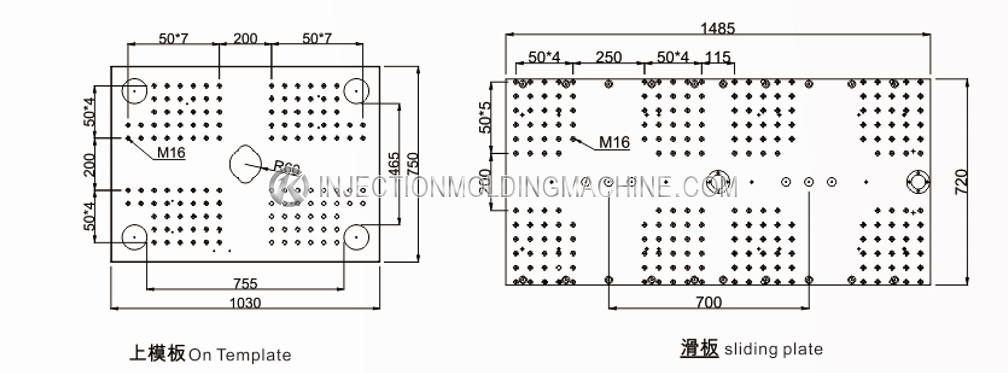

| KS-85T-2S | KS-120T-2S |

|  |

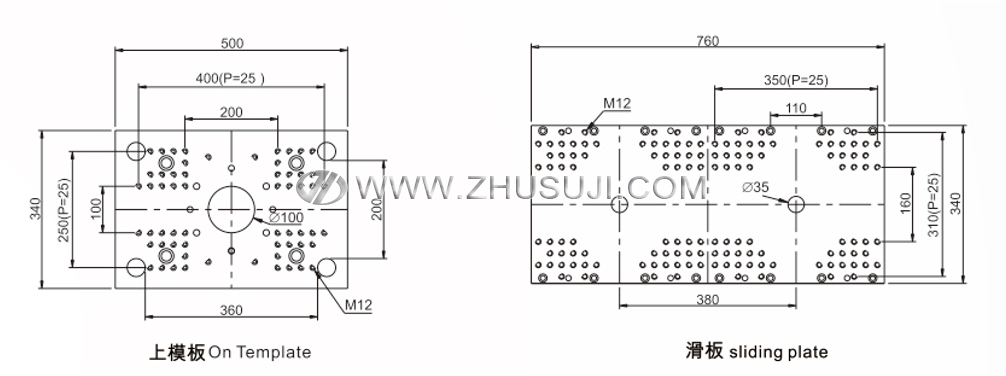

| KS-160T-2S | KS-200T-2S |

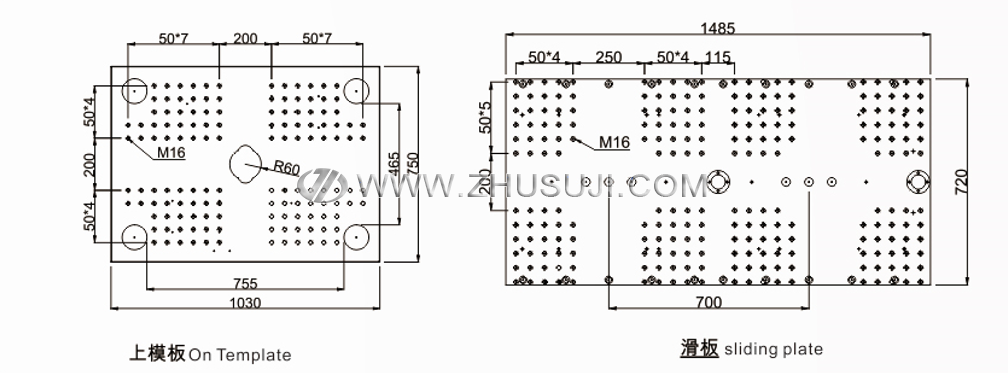

|  |

| KS-85T-2S | KS-120T-2S | KS-160T-2S | KS-200T-2S | ||||||||

| Ф32 | Ф36 | Ф40 | Ф36 | Ф40 | Ф45 | Ф45 | Ф50 | Ф55 | Ф55 | Ф60 | Ф65 |

| 113 | 142 | 176 | 162 | 201 | 254 | 318 | 393 | 475 | 570 | 678 | 796 |

| 105(3.7) | 132(4.6) | 164(5.8) | 151(5.3) | 187(6.6) | 236(8.3) | 296(10.4) | 365(12.8) | 442(15.6) | 530(18.6) | 630(22.2) | 740(26.1) |

| 229(2331) | 181(1842) | 146(1492) | 222(2268) | 180(1838) | 142(1452) | 218(2226) | 177(1803) | 146(1490) | 235(2406) | 198(2022) | 168(1722) |

| 94 | 118 | 146 | 124 | 154 | 195 | 178 | 220 | 266 | 214 | 254 | 298 |

| 116 | 123 | 112 | 90 | ||||||||

| 220(45T)/165(60T) | 285(45T)/217(60T)/153(85T) | 290(60T)/200(85T)/168(150T) | 225(120T)/148(150T) | ||||||||

| 0~300 | 0~300 | 0~300 | 0~180 | ||||||||

| ≥45 | ≥45 | ≥45 | ≥45 | ||||||||

| 833(85) | 1176(120) | 1568(160) | 1960(200) | ||||||||

| 250 | 280 | 300 | 350 | ||||||||

| 230(330) | 280(380) | 300(400) | 350(450) | ||||||||

| 480(580) | 560(660) | 600(700) | 700(800) | ||||||||

| 510*360 | 660*380 | 740*420 | 910*450 | ||||||||

| 470*400 | 580*540 | 710*630 | 750*620 | ||||||||

| 100 | 100 | 120 | 150 | ||||||||

| 45(4.6) | 45(4.6) | 45(4.6) | 45(4.6) | ||||||||

| 13.7(140) | 13.7(140) | 13.7(140) | 13.7(140) | ||||||||

| 310 | 410 | 850 | 920 | ||||||||

| 15(20) | 18.5(25) | 22.5(30) | 37.5(50) | ||||||||

| 2.0*1.5 | 2.2*1.8 | 2.7*2.0 | 2.9*2.1 | ||||||||

| 3.1 | 3.3 | 3.7 | 4.4 | ||||||||

| 3.3 | 6 | 8.1 | 12.5 | ||||||||

English

English