Clamping force:10T to 500T;

Injection weight: 35g to 850g;

Vertical four columns clamping,vertical injection, suitable for insert injection molding process;

We can upgrade to servo motor for customer's needcan save energy from 50% to 70%.

| Model | KS-15T | KS-20T | KS-35T | Unit | |||||

| Injection Unit | Screw Diameter | 26 | 28 | 22 | 28 | 26 | 28 | 32 | mm |

| Injection Pressure | 1715 | 1098 | 1416 | 875 | 1677 | 1446 | 1107 | Kgf/cm3 | |

| Theoretical Shot Volume | 55 | 65 | 40 | 65 | 61 | 71 | 93 | cm3 | |

| Max. Shot Weight | 51.2/1.8 | 59.4/2 | 36.7/1.29 | 59.4/2 | 56.6/2 | 65.5/2.3 | 85.7/3 | g/oz | |

| Injection Rate | 50 | 59 | 36 | 59 | 41 | 48 | 62 | cm3/s | |

| Screw Stroke | 105 | 105 | 116 | mm | |||||

| Screw Rotation Speed | 0-215 | 0-138 | 0-148 | rpm | |||||

| Nozzle Contact Force | ------ | 3.5 | 3.5 | Tons | |||||

| <>Nozzle Retraction Stroke | ------ | 120 | 150 | mm | |||||

| Stages of Temperature Control | 2 | 2 | 3 | ||||||

| Clamping Unit | Clamping Force | 15 | 20 | 35 | Tons | ||||

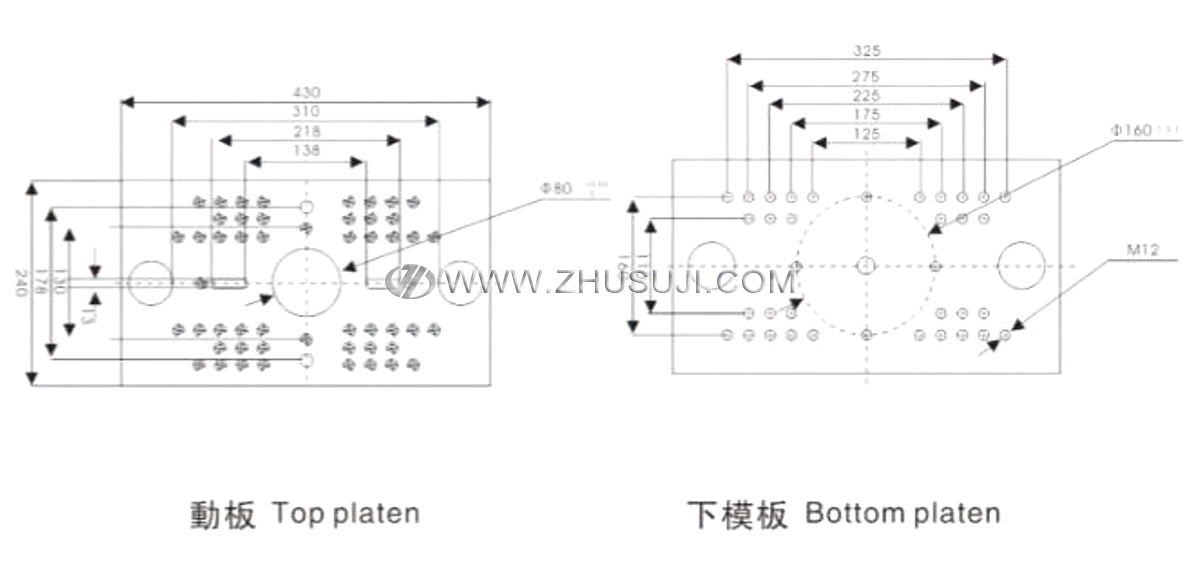

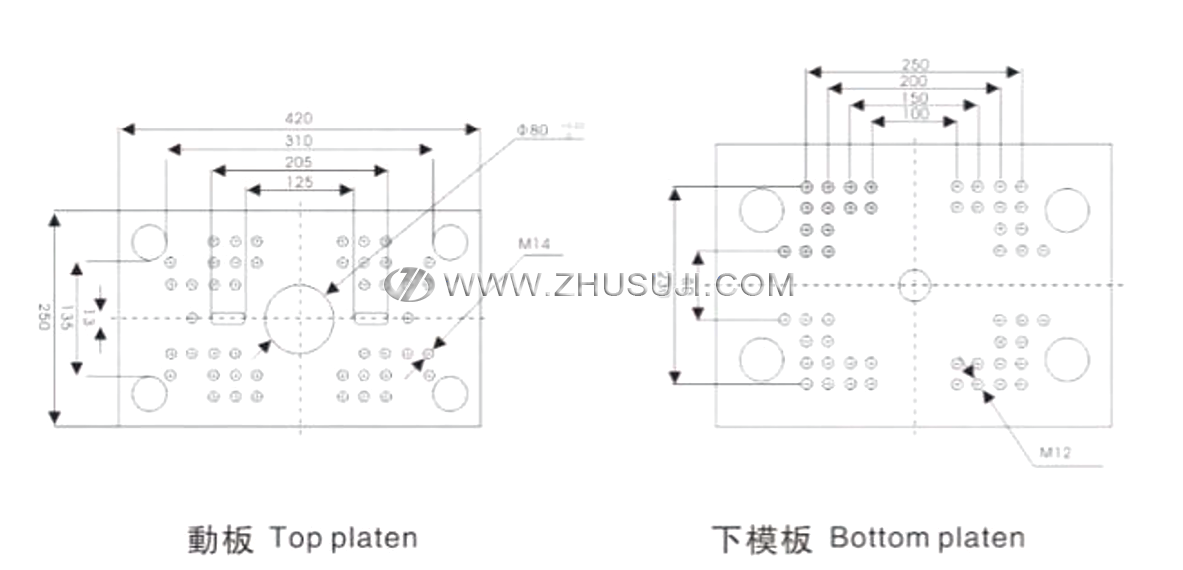

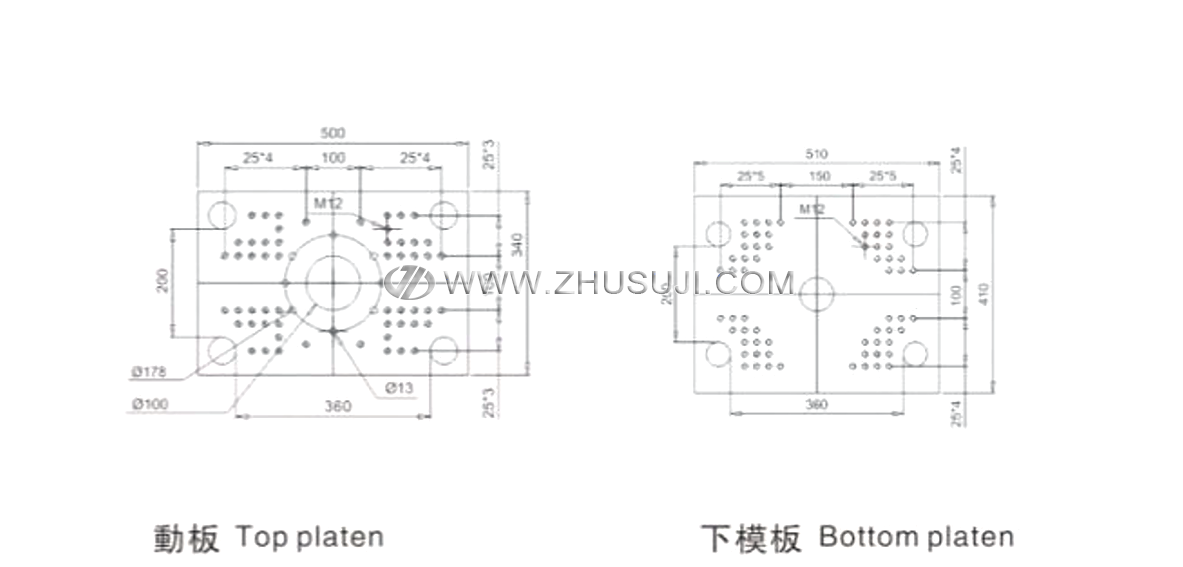

| Platen Size | 280*250 | 420*250 | 500*340 | mm | |||||

| Distance between Columns | 310 | 310*130 | 360*200 | mm | |||||

| Min. Mould Thickness | 35 | 35/100 | 60/145 | mm | |||||

| Opening Stroke | 198 | 198 | 215 | mm | |||||

| Max. Mould Opening Distance | 233 | 233/298 | 275/360 | mm | |||||

| Ejector Force | 1.3 | 1.3 | 1.3 | Tons | |||||

| Ejector Stroke | 35 | 35 | 35 | mm | |||||

| Hydraulic System | Max. Hydualic Pressure | 140 | 140 | 140 | Kgf/cm3 | ||||

| Oil Pump Output | 23 | 23 | 31 | cc/rec | |||||

| Cooling Water Consumping | 400-600 | 400-600 | 500-700 | L/h | |||||

| Motor Power | 2.2(3HP) | 2.2(3HP) | 4(5.5HP) | Kw | |||||

| Barrel Heating Power | 2 | 2 | 2.4 | Kw | |||||

| Total Wattage | 4.2 | 4.2 | 6.4 | Kw | |||||

| Machine Weight Net | 650 | 800 | 1200 | Kg | |||||

| Others | Machine Dimensions(L×W×H) | 1.15*0.75*2.15 | 1.2*0.8*2.2 | 1.45*0.9*2.5 | m | ||||

| Shipping Weight Gross | 650 | 850 | 1300 | Kg | |||||

| Shipping Dimension(L×W×H) | 1.4*1.0*2.3 | 1.5*1.0*2.3 | 1.6*1.1*2.2 | m | |||||

| KS-15T | KS-20T | KS-35T |

|  |  |

English

English