Clamping force: 10T to 500T;

Injection weight: 35g to 850g;

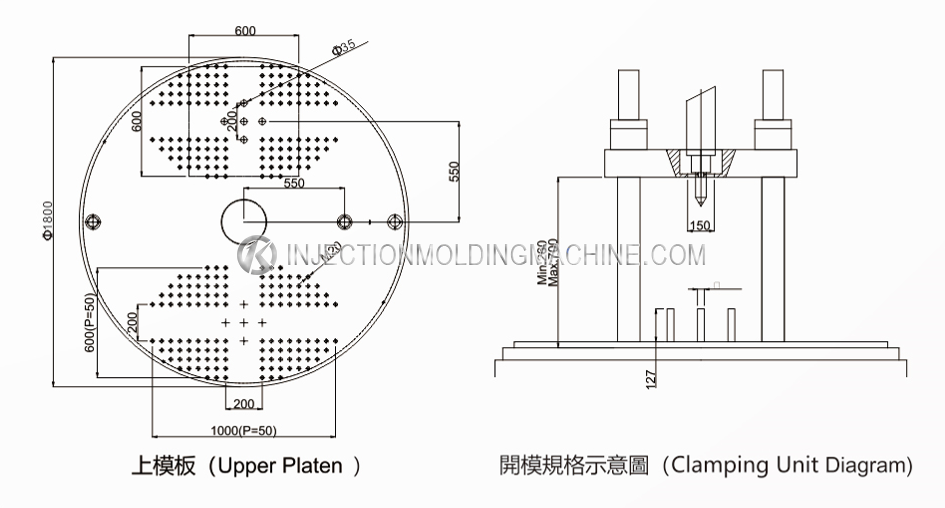

Vertical four columns clamping,vertical injection;

Suitable for insert injection molding process;

1 top mold, 2 bottoms mold design, turn out the clamping area by rotation;

Put insert part into outer mold and inner mold injection at the same time;

We can upgrade to servo motor for customer's need;

The actualenergy save 50%~70%.

| KS-2R-45T | KS-2R-60T |

|  |

| KS-2R-85T | KS-2R-120T |

|  |

| KS-2R-160T | KS-2R-200T |

|  |

| KS-2R-300T | |

|

| Model | KS-2R-45T | KS-2R-60T | Unit | ||||||

| Injection Unit | Screw Diameter | Ф25 | Ф28 | Ф32 | Ф28 | Ф32 | Ф36 | mm | |

| Theotetical Injection Volume | 63.8 | 80 | 104 | 80 | 104 | 132 | cm | ||

| Injection Weight(PS) | 59.3(2.1) | 74.4(2.6) | 96.7(3.4) | 74.4(2.6) | 96.7(3.4) | 122.9(4.3) | g(oz) | ||

| Max. Injection Pressure | 192(1960) | 153(1563) | 117(1195) | 212(2170) | 162(1661) | 128(1312) | Mpa(kgf/cm) | ||

| Injection Rate | 53 | 67 | 87 | 73 | 95 | 121 | cm/s | ||

| Injection Speed | 110 | 118 | mm/s | ||||||

| ★Speed Improvement | 220↑ | 164(45T) | mm/s | ||||||

| Screw Ratation Speed | 0~240 | 0~240 | r.p.m | ||||||

| Nozzle Out From Platens | ≧45 | ≧45 | mm | ||||||

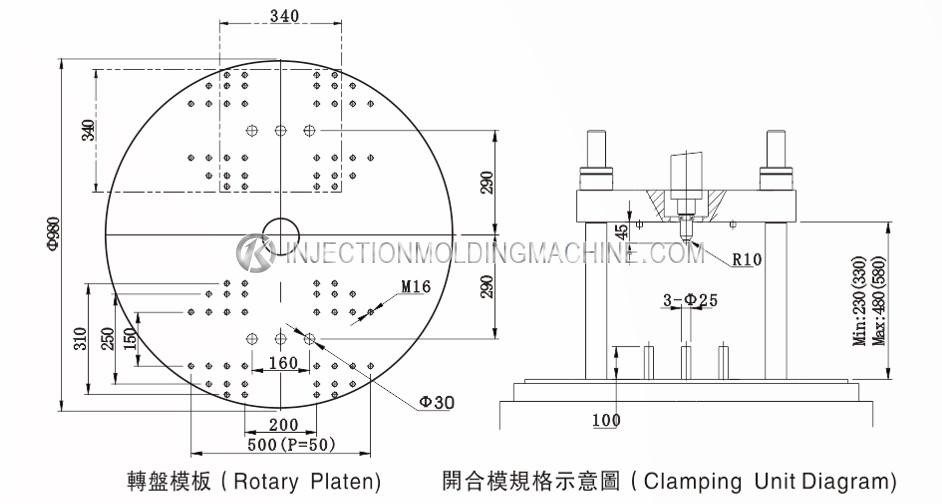

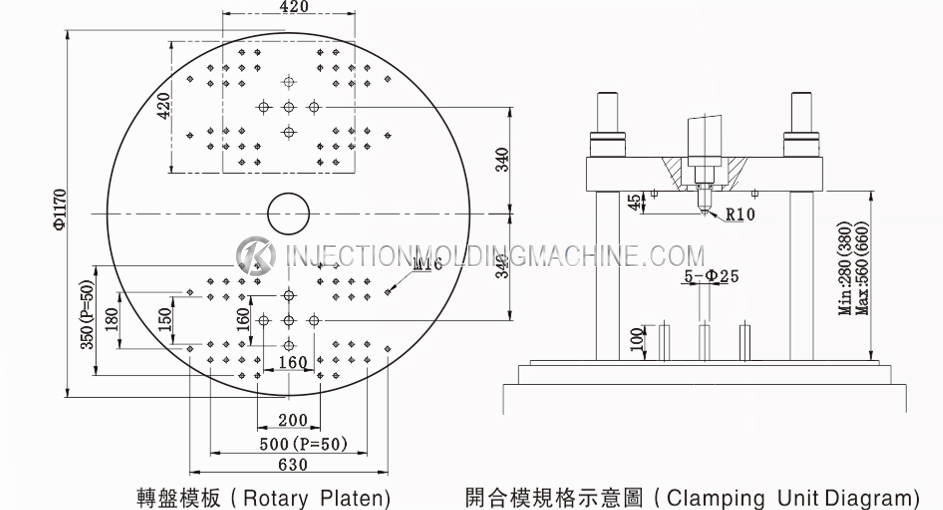

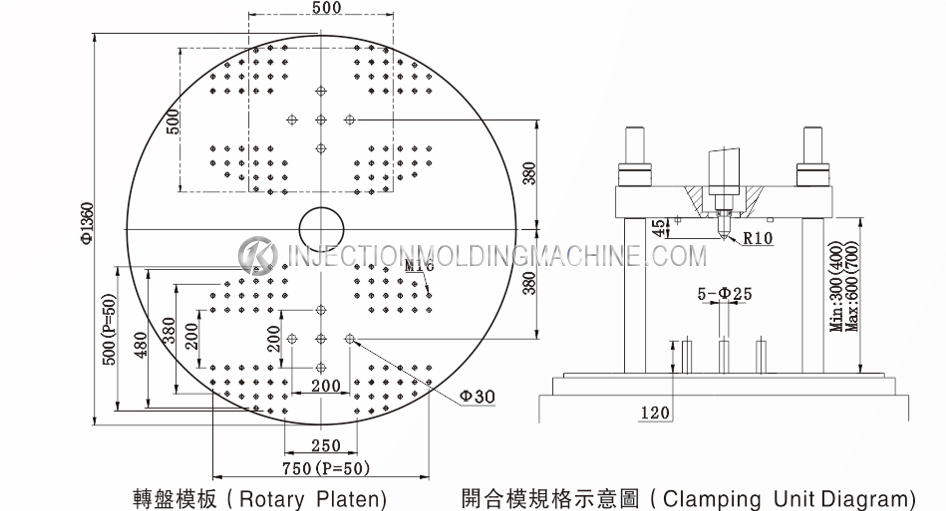

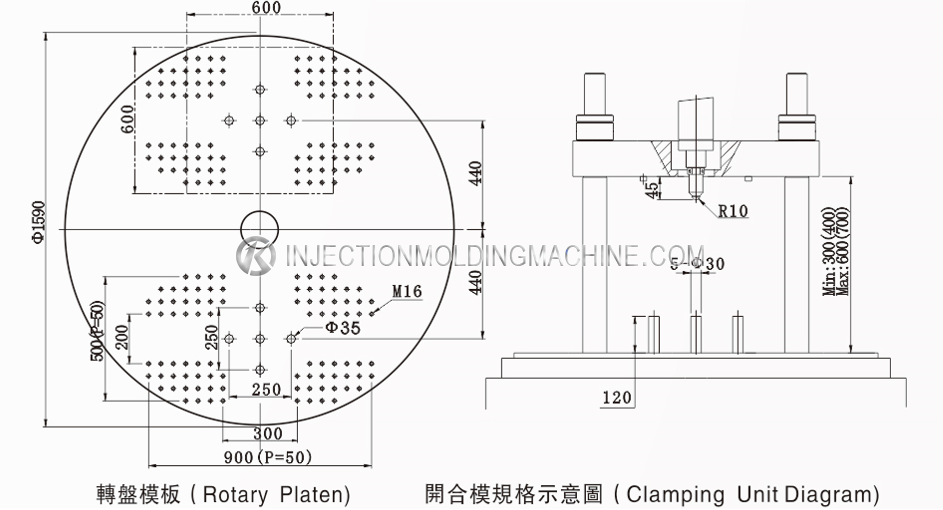

| Clamping Unit | Clamping Forece | 441(45) | 588(60) | KN(tf) | |||||

| Clamping Stroke | 200 | 200 | mm | ||||||

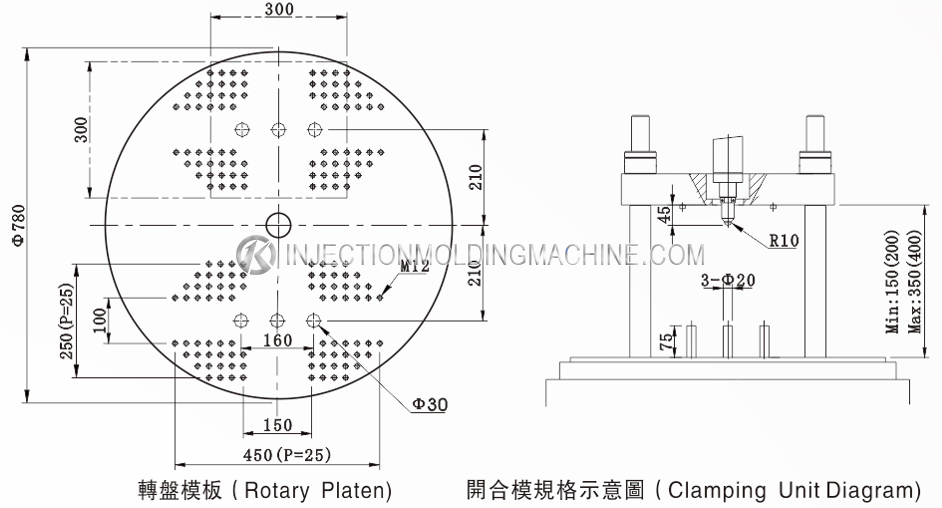

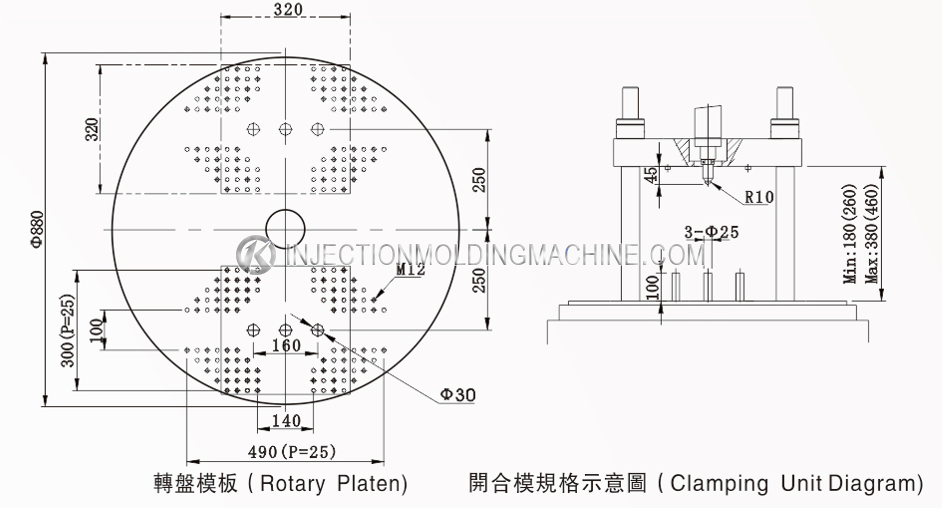

| Min. mold Thickness | 150(200) | 180(260) | mm | ||||||

| Max. opening | 350(400) | 380(460) | mm | ||||||

| Max. Mould Size(L*W) | 300*300 | 320*320 | mm | ||||||

| Diameter Of Rotary Table | Ф780 | Ф880 | mm | ||||||

| Ejector Distance | 75 | 100 | mm | ||||||

| Ejector Force | 26.5(2.7) | 26.5(2.7) | KN(tf) | ||||||

| Other | System Pressure | 13.7(140) | 13.7(140) | Mpa(kgf/cm) | |||||

| Oil Tank Capacity | 200 | 230 | L | ||||||

| Motor Power | 7.5(10) | 11(15) | KW(HP) | ||||||

| Machine Dimensions | L*W | 2*1.5 | 2.1*1.6 | M | |||||

| H | 2.8 | 3 | |||||||

| Machine Weight | 2.1 | 2.6 | tf | ||||||

| KS-2R-85T | KS-2R-120T | KS-2R-160T | KS-200T | JL-2R-200T | ||||||||||

| Ф32 | Ф36 | Ф40 | Ф36 | Ф40 | Ф45 | Ф45 | Ф50 | Ф55 | Ф55 | Ф60 | Ф65 | Ф65 | Ф70 | Ф75 |

| 113 | 142 | 176 | 162 | 201 | 254 | 318 | 393 | 475 | 570 | 678 | 796 | 1193 | 1384 | 1589 |

| 105(3.7) | 132(4.6) | 164(5.8) | 151(5.3) | 187(6.6) | 236(8.3) | 296(10.4) | 365(12.8) | 442(15.6) | 530(18.6) | 630(22.2) | 740(26.1) | 109.5(39.05) | 1287(45.3) | 1477.5(52) |

| 229(2331) | 181(1842) | 146(1492) | 222(2268) | 180(1838) | 142(1452) | 218(2226) | 177(1803) | 146(1490) | 235(2406) | 198(2022) | 168(1722) | 227(2319) | 196(2000) | 170(1742) |

| 94 | 118 | 146 | 124 | 154 | 195 | 178 | 220 | 266 | 214 | 254 | 298 | 401 | 465 | 534.3 |

| 116 | 123 | 112 | 90 | 121 | ||||||||||

| 220(45T)/165(60T) | 295(45T)/217(60T)/153(85T) | 290(60T)/200(85T)/168(160T) | 225(120T)/148(160T) | 220(45T)/165(60T) | ||||||||||

| 0~300 | 0~300 | 0~300 | 0~180 | 0~400 | ||||||||||

| ≥45 | ≥45 | ≥45 | ≥45 | ≥45 | ||||||||||

| 833(85) | 1176(120) | 1568(160) | 1960(200) | 2940(300) | ||||||||||

| 250 | 280 | 300 | 350 | 450 | ||||||||||

| 230(330) | 280(380) | 300(400) | 350(450) | 350(450) | ||||||||||

| 480(580) | 560(660) | 600(700) | 700(800) | 800(900) | ||||||||||

| 340*340 | 420*420 | 500*500 | 600*600 | 500*800 | ||||||||||

| Ф980 | Ф1170 | Ф1360 | Ф1590 | Ф1800 | ||||||||||

| 100 | 100 | 120 | 150 | 127 | ||||||||||

| 45(4.6) | 45(4.6) | 45(4.6) | 45(4.6) | 56.8(5.8) | ||||||||||

| 13.7(140) | 13.7(140) | 13.7(140) | 13.7(140) | 17.15(175) | ||||||||||

| 310 | 410 | 850 | 920 | 676 | ||||||||||

| 15(20) | 18.5(25) | 18.5(30) | 22(30) | 45(61) | ||||||||||

| 2.4*1.8 | 2.5*2.0 | 2.7*2.0 | 3.2*2.5 | 4.1*2.1 | ||||||||||

| 3.5 | 4.1 | 4.5 | 5.3 | 5.4 | ||||||||||

| 4.2 | 6.4 | 9.4 | 14 | 22.9 | ||||||||||

English

English