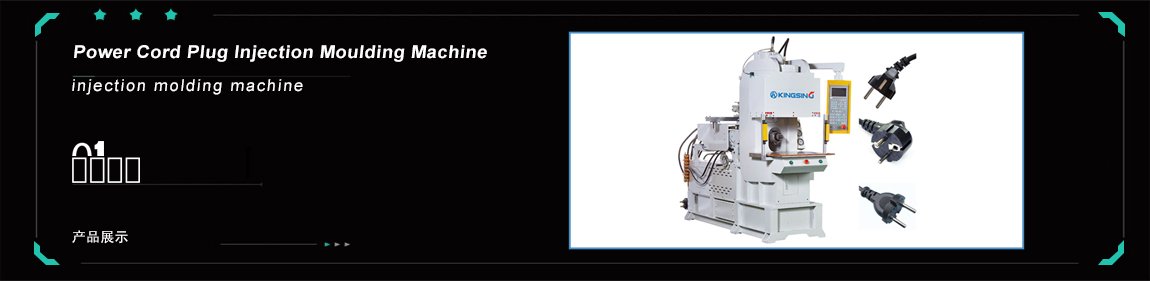

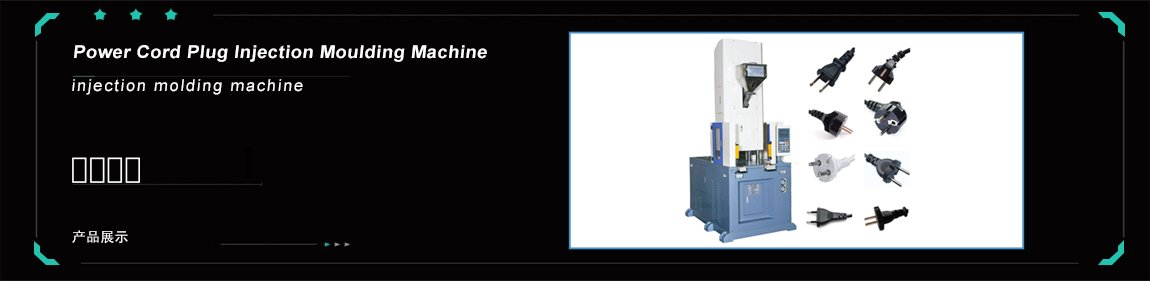

Clamping force:70T to 500T;

lnjection weight: 90g to 850g;

Vertical four columns clamping,horizontal injection suitable for big insert part injection molding process;

We can upgrade to servo motorfor customer's need;

The actual energy save 50%~70%.

| Model | KS-85T | KS-120 | KS-150 | KS-200 | Unit | |||||

| Injection Unit | Screw Diameter | 36 | 40 | 40 | 50 | 45 | 50 | 50 | 63 | mm |

| Injection Pressure | 1814 | 1020 | 1312 | 839 | 2212 | 1792 | 2020 | 1272 | kgf/cm2 | |

| Theoretical Shot Volume | 162 | 200 | 200 | 314 | 317 | 392 | 412 | 654 | cm3 | |

| Max. Shot Weight | 149/5.2 | 184/6.4 | 184/6.4 | 288.8/10.1 | 292.4/10.3 | 360 | 379/13.3 | 601.6/21.1 | g/oz | |

| Injection Rate | 81 | 100 | 160 | 250 | 76 | 118 | 142 | 226 | cm3/s | |

| Screw Stroke | 160 | 160 | 200 | 210 | mm | |||||

| Screw Ratation Speed | 0-180 | 0-160 | 0-160 | 0-155 | rpm | |||||

| Nozzle Contact Force | 4.3 | 4.3 | 4.3 | 4.3 | Tons | |||||

| Stages of temperature | 4 | 4 | 4+1 | 4+1 | ||||||

| Clamping Unit | Clamping Force | 85 | 120 | 150 | 200 | Tons | ||||

| Min. Mould Thickness | 200 | 250 | 300 | 300 | mm | |||||

| Opening Stroke | 250 | 280 | 350 | 350 | mm | |||||

| Max. Mould Opening Distance | 450 | 530 | 650 | 650 | mm | |||||

| Ejector Force | 2.7 | 4 | 4 | 5.4 | Tons | |||||

| Ejector Stroke | 60 | 100 | 100 | 100 | mm | |||||

| Hydraulic System | Max. Hydaulic Pressure | 140 | 140 | 140 | 140 | kgf/cm2 | ||||

| Motor Power | 11 | 15 | 18.5(25HP) | 22(30HP) | kw | |||||

| Barrel Heating Power | 8.3 | 10 | 10 | 15 | kw | |||||

| Total Wattage | 19.3 | 25 | 28.5 | 37 | kw | |||||

| Other | Machine Weight Net | 6500 | 7200 | 10000 | 12000 | kg | ||||

| Machine Dimensions(L×W×H) | 3.8*1.7*3.3 | 4.1*1.8*3.4 | 4.8*1.9*3.4 | 4.9*2.0*3.6 | m | |||||

| Shipping Dimensions(L×W×H) | 8000 | 8700 | 11200 | 13500 | kg | |||||

English

English